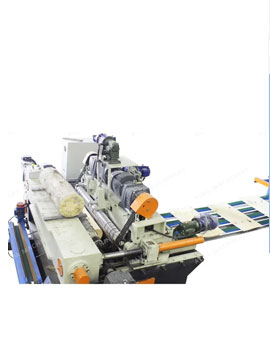

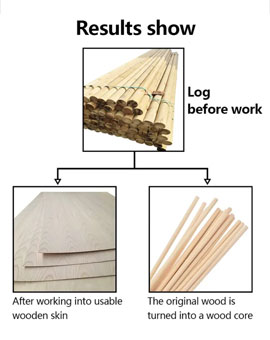

The 4 ft CNC veneer peeling machine is used to process wood segments of a certain length and diameter into continuous veneer strips for the production of plywood, fine wood upper boards and other wood-based panel veneers. The main technical parameters of the rotary cutting machine are that it can be processed Maximum length and diameter of wood segments.

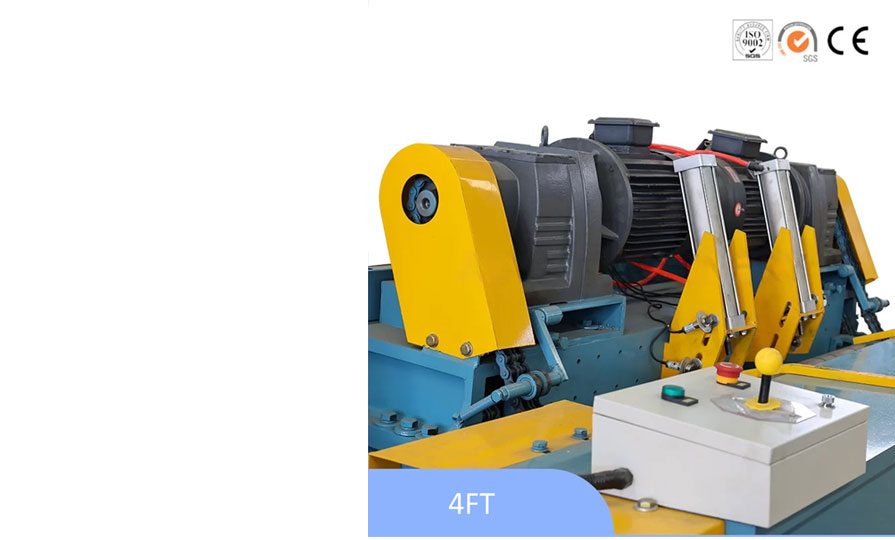

4 ft high-performance veneer peeling machine is used for peel the wood into face veneers. Face veneers can be laminated on the core veneers, to make the plywood better. Spindle-less plywood veneer peeling machine is most welcomed among plywood machinery.Heavy duty veneer peeling machine has high configuration, to guarantee the veneer quality. This model is suitable for hard wood, such as Eucalyptus,etc.

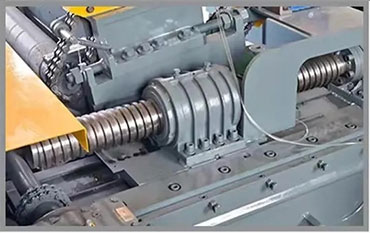

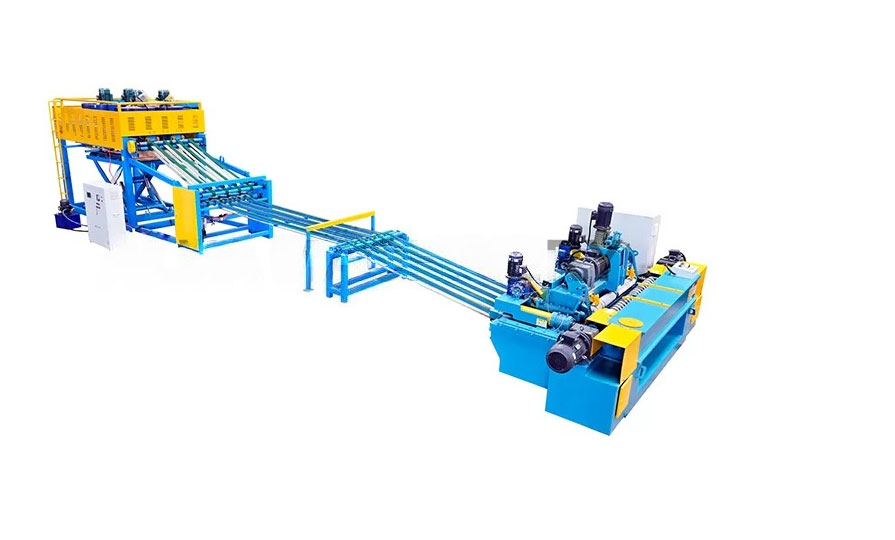

4 ft veneer peeling machine is fully automatic at high speed,You can set the speed to 40M/Min,50M/Min,60M/Min,70M/Min,80M/Min.many customers choose automatic veneer peeling machine to do high-speed automatic one support two veneer peeling production line,because it has the advantages of being dural power CNC,computer adjustment knife seam hydraulic pressure install knife,push back CNC.

CNC single spindle and without spindle combined peeling machine not only improves the quality and precision of the production of veneer, but also greatly improves the production efficiency and the degree of automation of the whole machine. The 4 feet veneer peeling machine is one of the main equipment for the production of plywood.

Rotary cutting machine is divided into clamping rotary cutting machine and no clamping rotary cutting machine,one of them is the clipping machine included CNC spindle and vertical spindle,each of these rotary cutting machines has its own advantages. If you want to know more about it, you can contact us.